The future-oriented alternative to gamma irradiation of medical devices

Gamma irradiation has been the usual method for sterilizing medical products for more than five dec-ades. However, there have been problems sourcing cobalt of late, calling into question whether this process is sustainable and efficient. X-ray irradiation has turned out to be a promising alternative, as it is a more environmentally friendly and cost-effective method that is accepted by the regulatory authorities and offers a number of advantages over gamma irradiation. Find out more about the chal-lenges of gamma irradiation and the compelling reasons for switching to X-ray irradiation in this arti-cle.

Uncertainty concerning cobalt sourcing for gamma sterilization

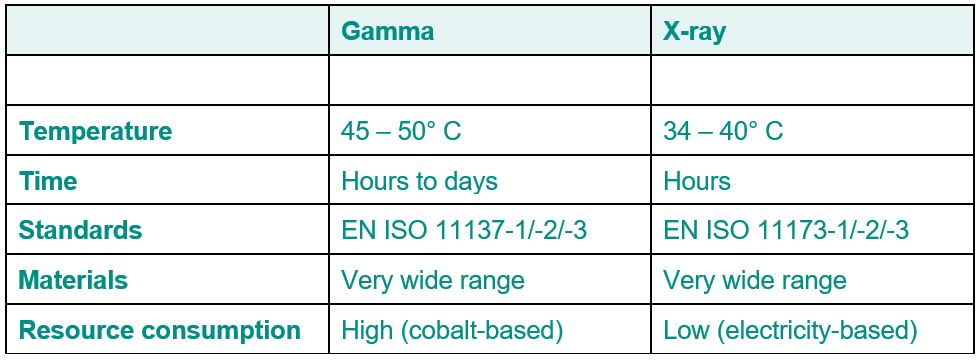

Gamma irradiation of medical products has been the state-of-the-art method for more than five dec-ades. Many products are treated with a minimum dose of 25 kGy in accordance with the validation process as per the EN ISO 11137-1/-2 standard and VDmax25 method. Gamma irradiation is defined as a clean and cold form of sterilization because no chemicals are used and the sterilization tempera-ture rarely exceeds 45° C. However, there have been increasing problems sourcing cobalt in recent years. Cobalt is used as a source of irradiation in most gamma equipment in the form of the radioac-tive isotope cobalt-60. Mining, processing and transforming cobalt-59 iron ore into cobalt-60 is a complex and expensive process. Furthermore, cobalt is becoming increasingly scarce. This is putting greater pressure on source operators, as cobalt-60 has a half-life of 5.27 years and cobalt sources must be replenished periodically in order to maintain activity and thus the strength of the source at the highest level possible. If the source strengthen wanes, this increases the irradiation duration for the medical product and results in backlogs if the source is not replenished in time. In addition, there is an increasingly critical view of transporting radioactive materials by land and by sea, resulting in in-creasingly stringent regulations. This has led to higher costs for source operators. Because of the controlled end storage of radioactive materials, gamma irradiation can be described as a clean tech-nology, but not a green one.

The environmental and economical alternative: Advantages of X-ray irradiation

One solution to the problem is X-ray irradiation, which has become increasingly popular in recent years. X-ray irradiation, also known as "bremsstrahlung," has the same basic effects as gamma irradi-ation on microbiological systems like bacteria, molds and yeasts. For this reason, X-ray irradiation is described in EN ISO 11137-1/-2 as equivalent to gamma irradiation and the validation requirements are exactly the same. However, X-ray irradiation has considerable advantages. For example, X-rays are produced by transforming or slowing accelerated electrons, while electrons are produced in a ma-chine by means of an electromagnetic field. The electrons are then accelerated to an energy level of up to 7 MeV. The X-ray machine works solely on the basis of electricity. Thus, there are no costs for cobalt and no transportation costs, as is the case with gamma irradiation. As with gamma irradiation, absolutely no chemicals are used in X-ray irradiation. Since there is also no necessity to dispose of waste or other materials, X-ray irradiation can be classified as a clean and green technology.

Why X-ray irradiation is the preferred method for sterilizing medical products

There are two other advantages. The first is that while X-rays have the same properties as gamma rays, their lower average level of energy means they do not penetrate materials as deeply as gamma rays do and thus represent a lower risk of structural modifications, especially in plastics. The second advantage is that there is a much lower thermal load on the products than is the case with gamma irradiation because the products are only exposed to the rays for a few seconds in total. As a result, the temperature does not climb as high as it does with products that are kept in a gamma irradiation room for several hours. For these reasons, it can be said that X-ray irradiation is the preferred method for treating medical products effectively and sustainably. X-ray irradiation is a clean and green tech-nology that is carried out under the same regulatory requirements as gamma irradiation and has the same effects on microbiological systems. X-ray irradiation is softer and produces a lower thermal load than gamma irradiation, which reduces the risk of transforming the product's characteristics. In addition, the operator of the irradiation equipment does not need to worry about sourcing cobalt and customers do not need to worry that equipment capacity will fall. X-ray irradiation is the method of the future and an increasing number of medical products will make the switch in the coming years from old methods like gamma and ethylene oxide to X-rays.

Did you know that we need less than 48 hours for sterilization and transport to you? And refrigerated goods only require 24 hours for Swiss customers.

If you have any further questions about the sterilization options, please contact our specialist Alexander Müller.

- Category:

- Year:

- 2023