Digitization of Zwick measuring equipment monitoring — an innovative step towards the future

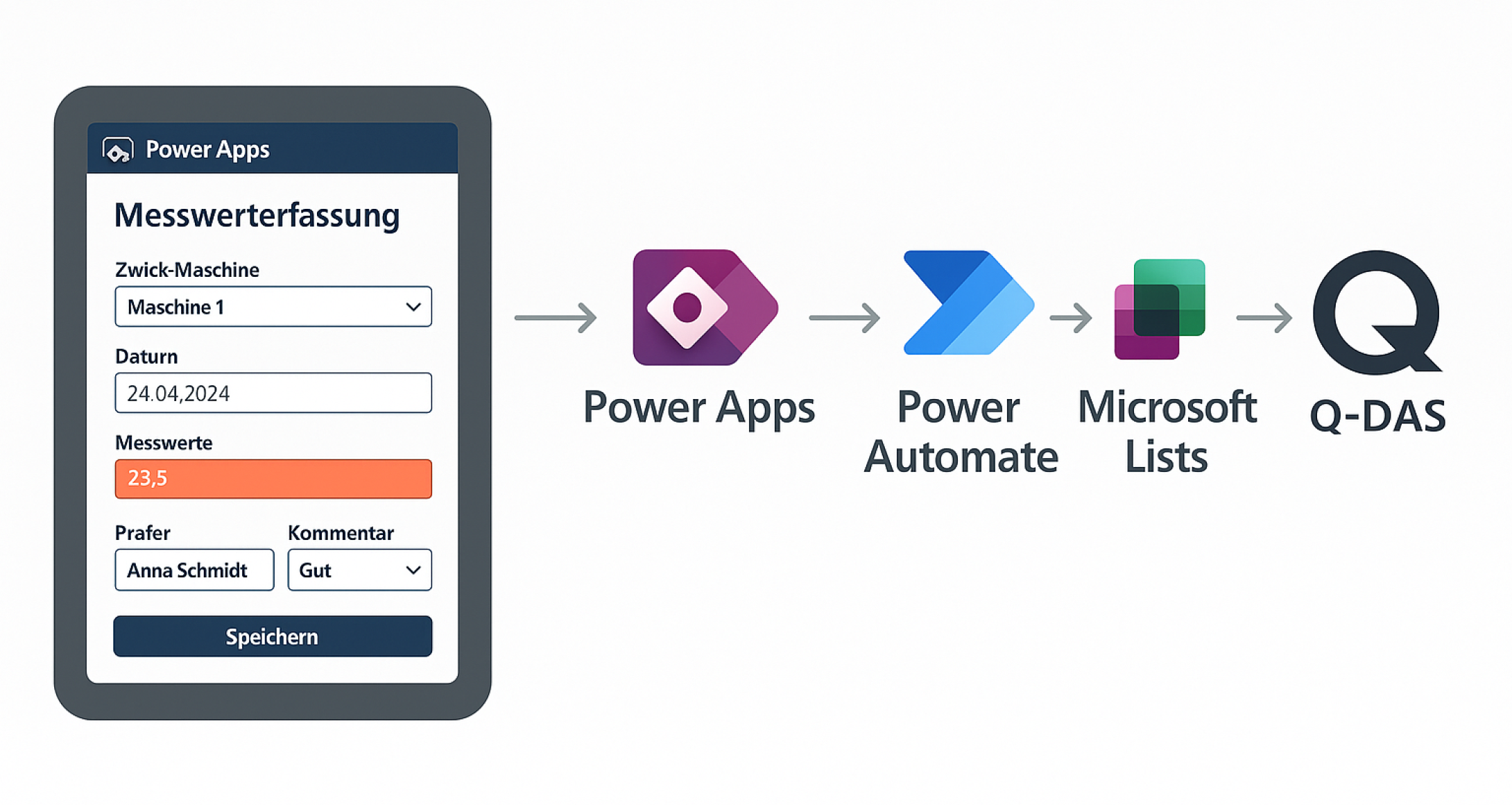

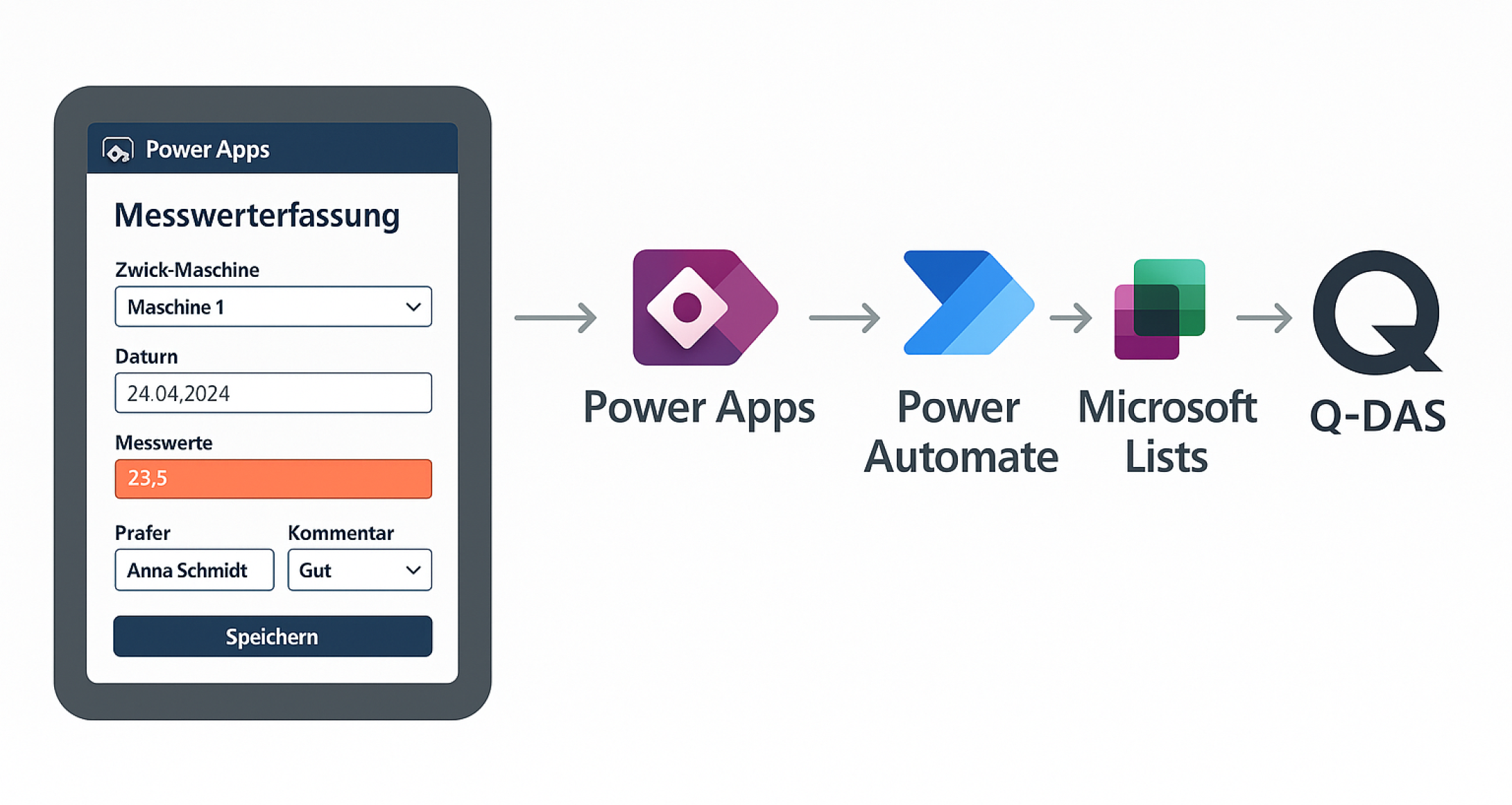

As part of our digitalization program, we have completely replaced the paper-based logging of Zwick measuring equipment monitoring. Six testing machines now record their measured values centrally via a customized Power App that is seamlessly integrated into the Microsoft 365 environment.

The aim was to avoid media disruptions, standardize processes and significantly improve traceability.

“The new solution enables us to achieve greater process reliability, save time and create a standardized database for reliable evaluations,” says Adem Hodza, Project Manager

The most important innovations at a glance:

- Digital input mask: Structured, validated data entry directly on the tablet — including mandatory fields and automatic tolerance check

- Automated workflows: Event-driven notifications and systematic archiving through Power Automate

- Central data storage: Securely stored in Microsoft Lists and Q‑DAS — accessible at any time

- Photo upload with dual control principle: Visual control and additional verification security

- GDPR-compliant data processing: automatic archiving and deletion routines including audit trail

Advantages at a glance:

- Paperless working — environmentally friendly and space-saving

- Increased data quality — thanks to structured input and central validation

- Greater security — thanks to standardized processes and traceable approvals

- Future-proof — flexibly expandable and systemically integrated

Technologies used at a glance:

| Technology |

|

|

Input & display of measurement data |

|

Process automation & Workflows |

|

Data storage & documentation |

|

Quality evaluation & data archive |

Neugierig geworden?

Kontaktieren Sie uns gern für weitere Informationen zu unseren digitalen Lösungen. Please use our contact form.

- Category:

- FRÜH-Know-how

- Year:

- 2025